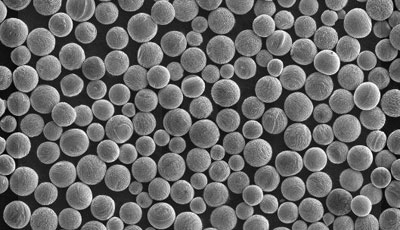

3d printing tungsten is a type of tungsten that’s been developed exclusively to printing 3D. This powder is meticulously produced to help make the kind of a rounded that’s why each powder compound being exceedingly homogeneous and small in amounts, allowing for excellent making results.

What’s tungsten powder?

Tungsten powder is a credit card applicatoin of powdered metallic tungsten, employed as a brand new item for the preparing of tungsten-processed materials such as for example alloys, tungsten products and. It is really a gray-black metal with a metallic Lustre (body-centred cubic crystal). Reduction stage 3400. Boiling facets 5555. The tungsten’s hardness is probably the most difficult of the metals. The hardest tungsten pole is 200250 and it is the hardest tungsten pole that’s been spun after the turning hammer revolves is 350400. It’s soluble within the mix p of nitric p along with hydrofluoric acid. It details in the mix of sodium hydroxide and carbonate. Just a little soluble in nitric p and sulfuric p along with aqua regia, insoluble in hydrofluoric p and water. potassium hydroxide. Tungsten has two forms A and B. At normal temperature and atmospheric force, type A is really a stable round style that is body-centered. Sort T tungsten is ready can be found in the presence of oxygen. It’s secure to 630degC, and then switches to a tungsten at problems around 630degC. This process is unreversible.

Huge difference between tungsten powder and rounded tungsten powder

Tungsten powder and tungsten rounded powder are both powder kinds of tungsten, but they have apparent modifications in morphology, compound measurement and application.

Morphology

Tungsten powder is typically in granular range, while rounded tungsten powder is really a rounded powder subsequent certain processing. This rounded shape enables tungsten powder to movement and fill higher in applications such as for example 3D making, giving more uniform making results.

Substance Measurement

While tungsten cereals have somewhat major compound designs, rounded tungsten cereals have really fine compound designs, typically in the nanometer range. This fine compound measurement enables Circular Tungsten Dust to suit higher into the nozzle of the 3D printer, giving higher printing details. Simultaneously, the fine particles may also be capable to fill the printing sleep, raising the occurrence and power of the printed part.

Applications

Tungsten powder features a wide selection of applications in several areas, such as for example light production, technology, and bodily parts. In these applications, tungsten powder is often applied as a product or alloying element. Circular tungsten powder, on an added hand, is quite well suited for parts such as for example 3D making, wherever it is ready of fabricating harder, high-precision pieces and products because excellent flowability, stuffing impact and printability.

How can you make tungsten powder?

It’s produced by the hydrocarbon reduce on tungsten trioxide, or ammonium paratungstate. The process of making the tungsten powder through hydrogen reduce could be split into two stages one time in the initial point, at problems of 500-700degC, tungsten oxide is reduced to tungsten oxide; within the next phase, at 700-900°D which stage tungsten dioxide will undoubtedly be reduced to the tungsten powder. The reduce impact is typically done by the correct performance of a pipe or rotary furnace.

The effectiveness of tungsten reduced powder (such as quality along with compound measurement, layout, measurement, etc.) mainly depends in the technique of reduction. In the act of decreasing tungsten within an oven tube, the principal facets that influence the charge of reduce are problems of reduce, amount of tungsten oxide into the burner vessel and the pace of activity that the vessel is in, along with the charge of movement of hydrogen, and the total amount of humidity in hydrogen. While the problems of reduce, measurement of tungsten powder gets more coarse.

Manufacturing of tungsten powder along with way of hydrogen reduce, there’s also a tungsten oxide carbon reduce practices employed originally The reduce temperature is significantly more than 1050 levels Celsius.The love of the tungsten oxide powder that is produced that way is poor. Furthermore, with the usage of calcium, aluminum zinc, and some other reduce functions of tungsten oxide study is underway. For specific applications that want ultra-fine, ultrapure compound measurement of tungsten powder the progress of the tungsten chloride hydrogen reduce method The tungsten powder compound measurement is significantly less than 0.05mm.

Commercial production can be performed through the reduced total of tungsten trioxide by hydrogen, or ammonium partungstate is treated with p and then tungsten trioxide could be produced by maturation decomposition and then reduced applying hydrogen.

Hydrogen reduce applying tungsten trioxide hydrogen reduce could be achieved in two measures The very first point is when tungsten trioxide heating to 550-800 , applying hydrogen reduction. Another point of reduce takes place between 650 and 850 the tungsten powder is finished.

Also, it is possible to scale back ammonium paratungstate in to blue tungsten oxide (blue tungsten) actually by hydrogen, or, or even by hydrogen then minimize it back again to tungsten by hydrogen. The measurement and substance of the tungsten powder really are a significant quality signal of the tungsten powder. The reduce method is completed by way of a tube or the rotary furnace.

Circular tungsten powder has these advantages:

Circular shape: The rounded shape enables the tungsten powder to higher fill the printing sleep through the making method, giving an even more uniform printing result. Considered against standard granular tungsten powder, rounded tungsten powder can higher adapt to the 3D making mind and present a simpler making process.

Good compound measurement: The fine compound measurement enables the tungsten powder to higher fit into the nozzle of the 3D printer, giving higher printing details. The fine particles also fill the printing sleep higher, raising the occurrence and power of the printed part.

Uniform compound flow: Uniform compound flow reduces clogging and weaknesses through the making method and increases printing success. In standard granular tungsten cereals, the compound flow is typically perhaps not uniform enough, which may result in clogging or weaknesses through the making process. The uniform compound flow of rounded tungsten powder can effortlessly resolve that problem.

High love: High-purity tungsten powder can provide higher printing efficiency and greater printing quality. In a couple of applications, it is required to employ high-purity item for making to guarantee the quality and efficiency of parts.

Circular Tungsten Dust Program Places

Circular tungsten powder features a wide selection of applications, including while not on a these parts:

Aerospace: Circular tungsten powder may be used to make high-performance pieces such as for example aircraft structural parts and engine parts. In these applications, the large power, large occurrence and large love features of tungsten powder can provide higher making efficiency and quality.

Automotive market: Circular tungsten is helpful for the production of pieces for automobiles, including frame pieces, engine parts and various parts. The stable longevity and opposition to temperature of tungsten powder can improve making quality and performance.

Medical topic Circular tungsten may be used to create medical products like dental implants, medical units and others. The large biocompatibility along with the large power of tungsten powder can improve printing quality and making performance.

Architecture: Circular tungsten powder may be used to make architectural versions and components. The large power and wear-resistant qualities of tungsten powder can provide higher making efficiency and quality.

Engineering: Circular tungsten powder may be used to make electronics, such as for example semiconductor products, world sections and therefore on. The large thermal and electric conductivity of tungsten powder can provide higher making efficiency and quality.

It must be observed that applying rounded tungsten powder for 3D making requires a particular amount of ability and experience. If you’re a novice, it is chosen to apply with some more accessible 3D making materials first. Simultaneously, applying tungsten powder for 3D making also requires certain focus on protection, as tungsten is really a high-density metal that’ll merely trigger damage to the patient body. When that, be sure to follow the applicable protection regulations and working procedures.