Plumbing maintenance might not be the most glamorous topic, but it’s crucial for the functioning and longevity of our infrastructure. Traditional methods of repairing damaged pipes have been known for their disruptions, costs, and inconvenience. However, the future of plumbing maintenance looks promising with advancements in pipe relining technologies. In this blog, we’ll delve into the innovations reshaping the plumbing industry and how relining solutions is becoming a game-changer.

The Challenge of Traditional Pipe Repairs: For decades, fixing damaged pipes often involved extensive excavation, which meant disrupting landscapes, tearing down walls, and causing inconvenience to residents or businesses. Not only was this process time-consuming and labor-intensive, but it also incurred significant costs. Moreover, it posed environmental concerns due to the excavation and disposal of materials.

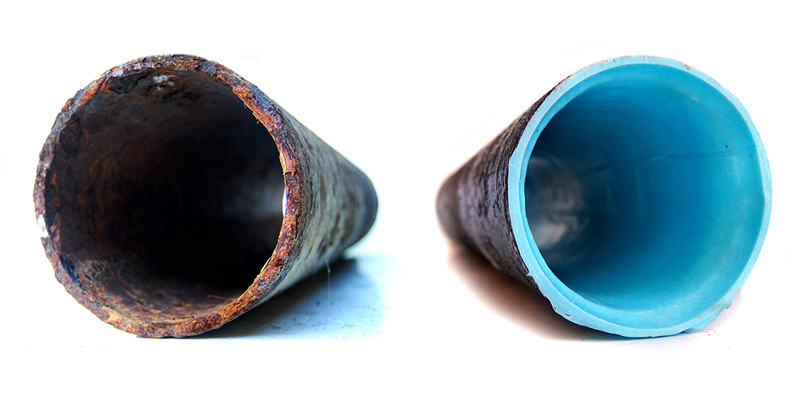

Innovations in Pipe Relining: Pipe relining, also known as trenchless pipe repair, has emerged as a revolutionary alternative to traditional methods. This technique involves rehabilitating existing pipes without the need for excavation. Instead of replacing the entire pipe, a liner is inserted into the damaged pipe and cured in place, creating a new, seamless pipeline within the old one.

Here are some key innovations driving the advancement of pipe relining:

- Advanced Materials: Modern pipe relining solutions utilize durable materials such as epoxy resin, fiberglass, or composite materials. These materials are resistant to corrosion, root intrusion, and chemical damage, ensuring the longevity of the repaired pipes.

- Cured-in-Place Pipe (CIPP) Technology: CIPP technology involves inserting a flexible liner saturated with resin into the damaged pipe. Once in place, the liner is inflated and cured using heat or ultraviolet light, forming a rigid, corrosion-resistant pipe within the existing one. This method is highly effective for repairing cracks, leaks, and structural defects.

- Robotic Inspection and Installation: Robotic systems equipped with cameras and sensors allow for precise inspection of pipelines without the need for excavation. These robots can identify defects, measure pipe dimensions, and guide the installation of liners with unparalleled accuracy, reducing human error and minimizing disruptions.

- Structural Lining Solutions: In addition to repairing damaged pipes, structural lining solutions offer reinforcement for deteriorating or aging pipelines. These liners provide added structural strength, preventing collapses and extending the lifespan of the infrastructure.

Benefits of Pipe Relining: The adoption of pipe relining technologies offers numerous benefits for property owners, municipalities, and the environment:

- Minimal Disruption: Pipe relining eliminates the need for excavation, reducing disruptions to residents, businesses, and traffic.

- Cost-Effectiveness: By avoiding costly excavation and restoration work, pipe relining can result in significant cost savings compared to traditional repairs.

- Faster Completion: Pipe relining projects can be completed in a fraction of the time required for traditional repairs, minimizing downtime and inconvenience.

- Environmental Sustainability: Trenchless pipe repair methods produce less waste and have a lower environmental impact compared to excavation-based techniques.

The Future Outlook: As the demand for efficient, cost-effective, and environmentally friendly infrastructure solutions continues to rise, the adoption of pipe relining technologies is expected to accelerate. Advancements in materials, robotics, and installation techniques will further enhance the effectiveness and reliability of pipe relining systems.